Talk to us

08045811615

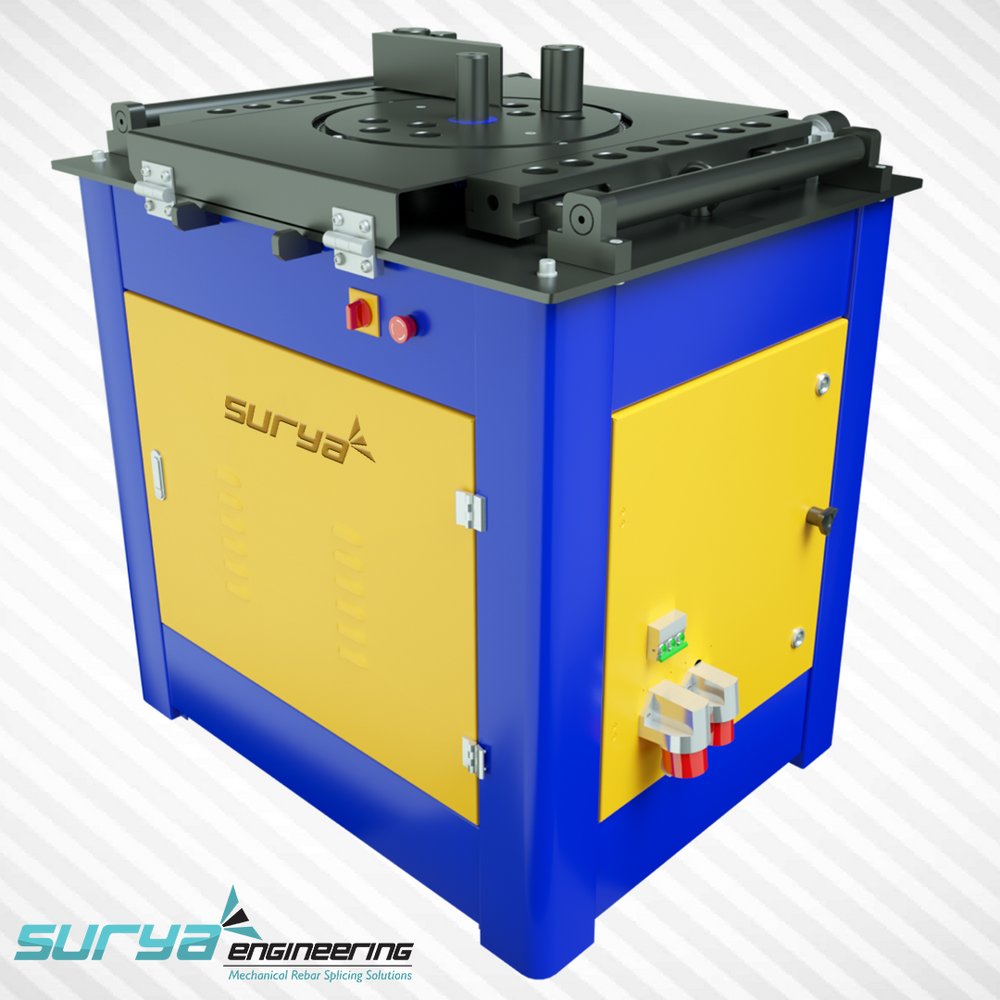

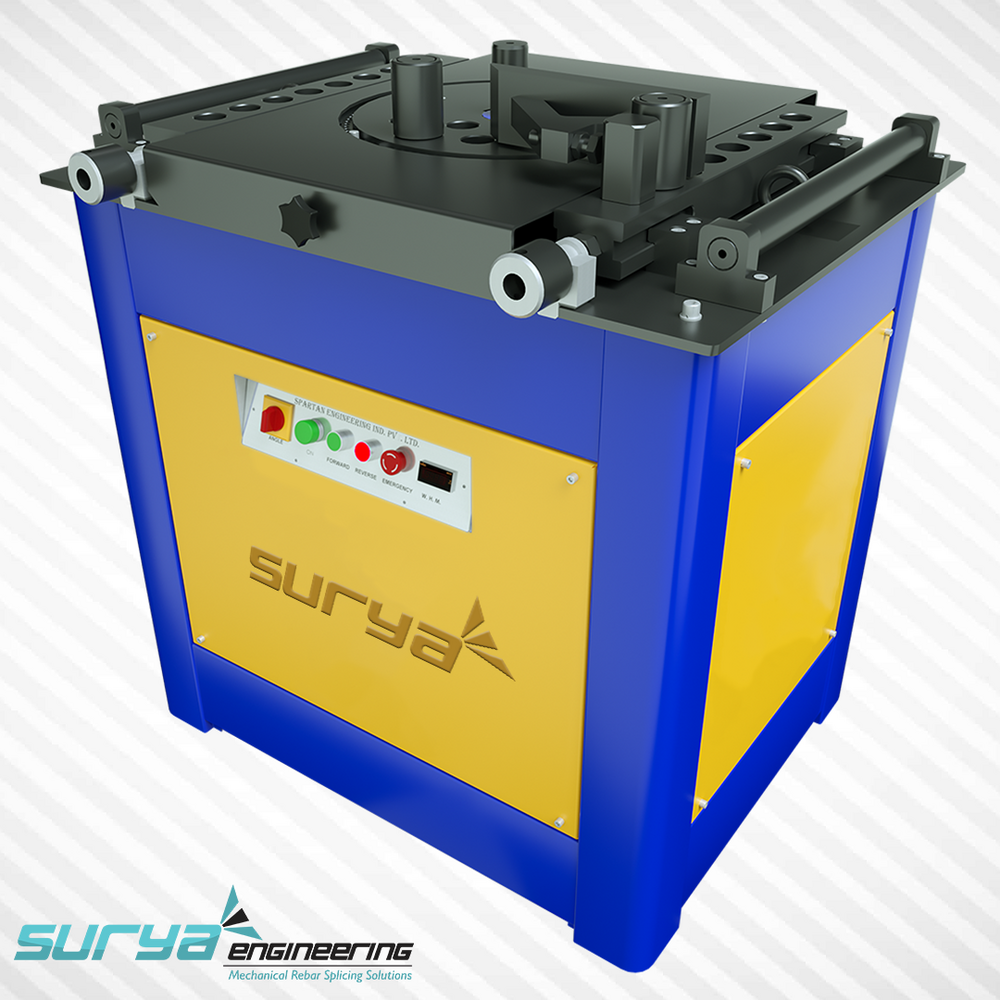

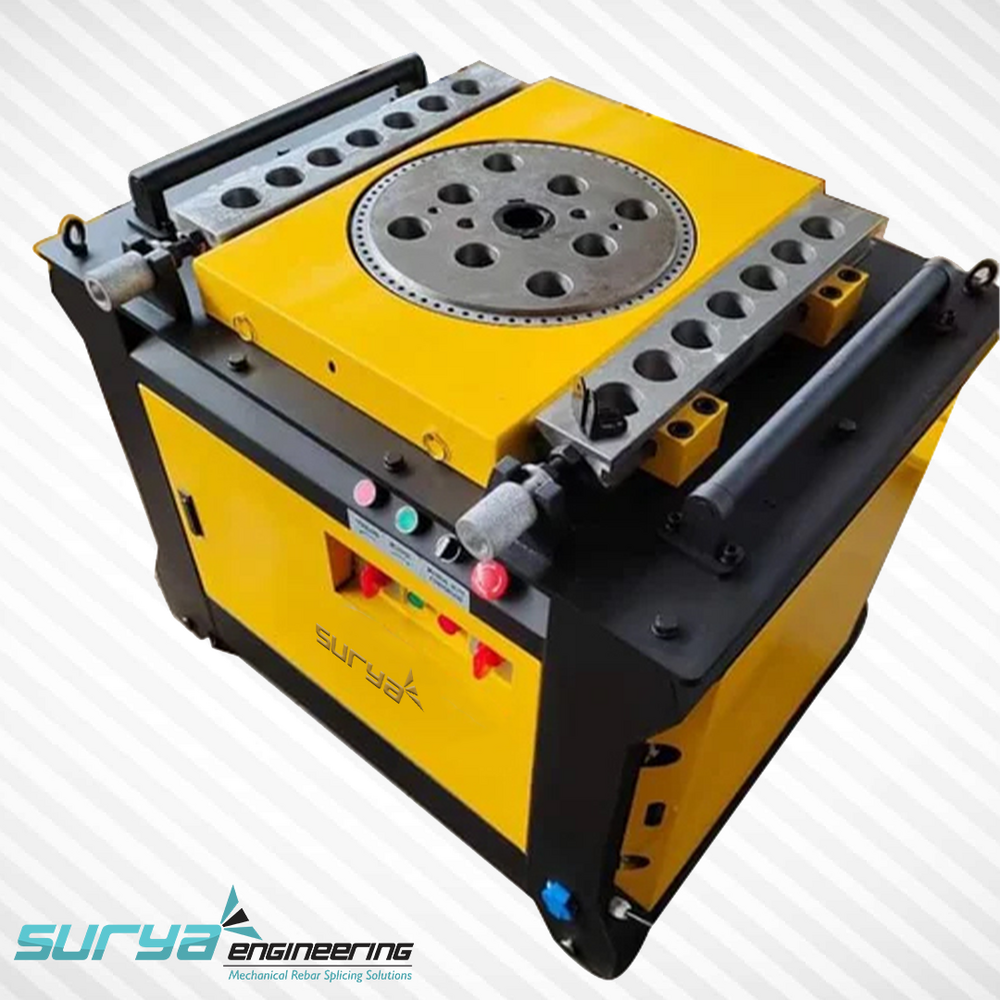

A Bar Bending Machine is a heavy-duty industrial tool designed to bend steel bars, rebar, rods, and metal profiles into precise shapes and angles required for construction, manufacturing, and infrastructure projects. Essential for reinforcing concrete structures, this machine ensures accuracy, efficiency, and safety in bending operations, replacing labor-intensive manual methods. It is widely used in construction sites, workshops, and factories to produce stirrups, U-hooks, spirals, and custom bends for beams, columns, and slabs.

High Precision Bending:

Programmable CNC controls or manual settings for accurate bend angles (0“180) and repeatability (±1 tolerance).

Adjustable rollers and dies to accommodate various bar diameters (6 mm“50 mm).

Robust Construction:

Frame: Heavy-duty steel or cast iron for stability and vibration resistance.

Bending Arms/Disks: Hardened alloy steel or chromium-plated components for durability.

Versatile Operation:

Manual, semi-automatic, or fully CNC-controlled models.

Compatible with round, square, flat, and TMT bars.

Safety Mechanisms:

Emergency stop buttons, protective guards, and overload sensors.

Compliance with CE, ISO, and OSHA safety standards.

Ease of Use:

Intuitive touchscreen interface (for CNC models) with pre-set bending programs.

Quick-change tooling for fast transitions between bending tasks.

Construction: Bending rebar for concrete reinforcement in buildings, bridges, and highways.

Manufacturing: Creating metal frames, grilles, and decorative elements.

Infrastructure: Bending steel for pipelines, tunnels, and railway tracks.

Precast Concrete: Forming stirrups and cages for prefabricated structures.

Bending Capacity: 6 mm“50 mm (varies by model).

Bending Speed: 10“30 bends per minute (CNC models).

Power Supply: 3-phase electric motor (5 HP“15 HP) or hydraulic drive.

Dimensions: Compact to industrial sizes (portable or stationary).

Weight: 500 kg“2,000 kg (depending on capacity).

Time & Labor Savings: Automates complex bending tasks, reducing manual effort by 70“80%.

Material Efficiency: Minimizes rebar waste with precise measurements.

Consistency: Ensures uniform bends for structural integrity.

Cost-Effective: Low maintenance and long-lasting components.

Scalability: Suitable for small workshops to large-scale construction sites.

Price: