Talk to us

08045811615

TheNbeson Threading Chaseris a precision cutting tool designed for creating, repairing, or cleaning external and internal threads in machining, automotive, and industrial applications. Its material composition is engineered for durability, wear resistance, and consistent performance. Below is a detailed breakdown of its key materials and their roles:

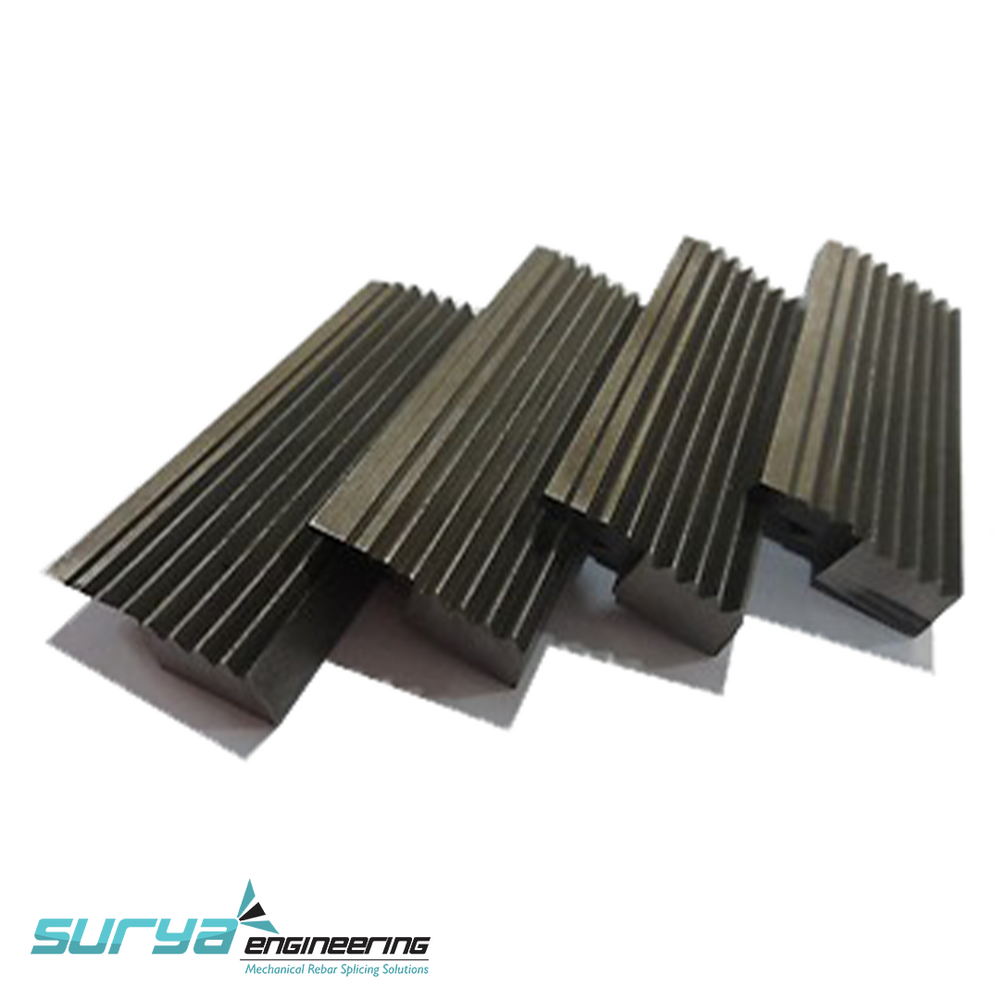

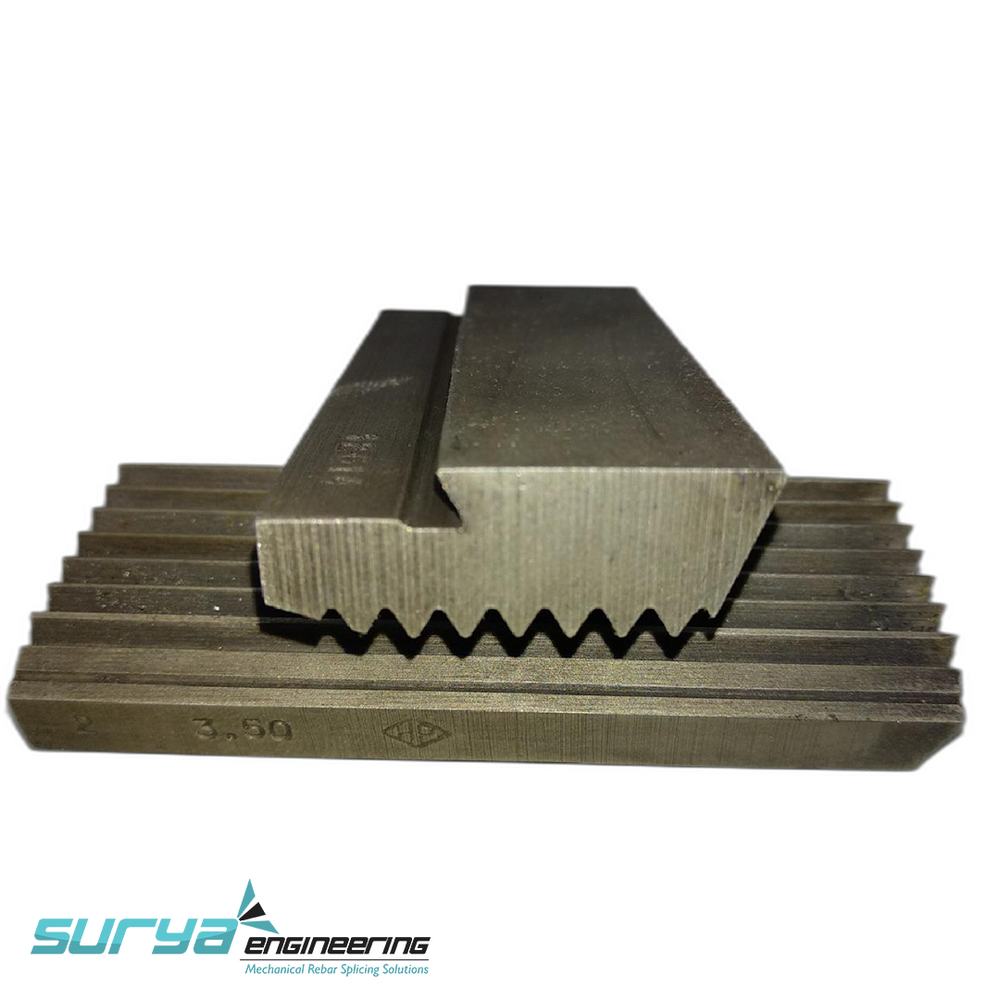

Cutting Teeth/Inserts

High-Speed Steel (HSS):

Grade M2/M35:Hardened to6265 HRCfor exceptional wear resistance and edge retention.

Retains hardness even at high temperatures generated during threading.

Carbide (Tungsten Carbide):

Grade K10/K20:Used in premium chasers for superior hardness (9092 HRA) and longevity in high-speed or abrasive applications.

Coatings:

Titanium Nitride (TiN):Reduces friction, enhances heat resistance, and extends tool life.

Titanium Aluminum Nitride (TiAlN):Ideal for high-temperature threading (e.g., stainless steel, alloys).

Chaser Body/Shank

Alloy Steel (4140/4340):

Heat-treated to4045 HRCfor toughness and resistance to bending or deformation.

Stainless Steel (Grade 420/440C):

Used in corrosion-prone environments (e.g., marine, chemical industries).

Thread Profile Geometry

Precision-ground usingCBN (Cubic Boron Nitride)ordiamond abrasivesfor sharp, accurate thread forms.

Fastening Components

Hardened Steel Screws:Secure inserts and maintain alignment during operation.

High Wear Resistance:

Carbide and HSS teeth withstand abrasive materials (e.g., stainless steel, cast iron).

Heat Resistance:

TiN/TiAlN coatings reduce thermal degradation, enabling high-speed threading.

Durability:

Reinforced alloy steel bodies resist chipping and fatigue under repetitive loads.

Corrosion Resistance:

Stainless steel variants thrive in humid or chemical environments.

Precision:

Ultra-sharp edges and optimized geometries ensure accurate thread pitch and depth.

Machining:Threading bolts, screws, pipes, and hydraulic fittings.

Automotive:Repairing engine block threads, axle shafts, and transmission components.

Oil & Gas:Threading drill pipes, valves, and flanges.

Aerospace:Precision threading for high-strength alloy components.

MeetsISO 13399(cutting tool standards) andDIN/ANSIspecifications.

Certified for use in CNC machines and manual lathes.

Premium Materials:Engineered for maximum tool life and minimal downtime.

Customization:Available in metric, UNC, UNF, and custom thread profiles.

Versatility:Compatible with steel, aluminum, brass, and exotic alloys.

Cost Efficiency:Reduces rework and replacement costs with reliable performance.

Price:

Price Range 3600.00 - 4200.00 / Piece

Price 3600 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Alloy Steel (Case hardened and tempered)

Feature : High surface hardness, Wear resistance, Precision ground

Price 3800.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Usage : CONSTRUCTION

Price 2650 INR / Set

Minimum Order Quantity : 1 Set

Material : M2

Usage : Industrial

Feature : Corrosion Resistance

Price 5200 INR / Set

Minimum Order Quantity : 1 Set

Material : Mild Steel

Usage : Construction

Feature : Corrosion Resistance