Talk to us

08045811615

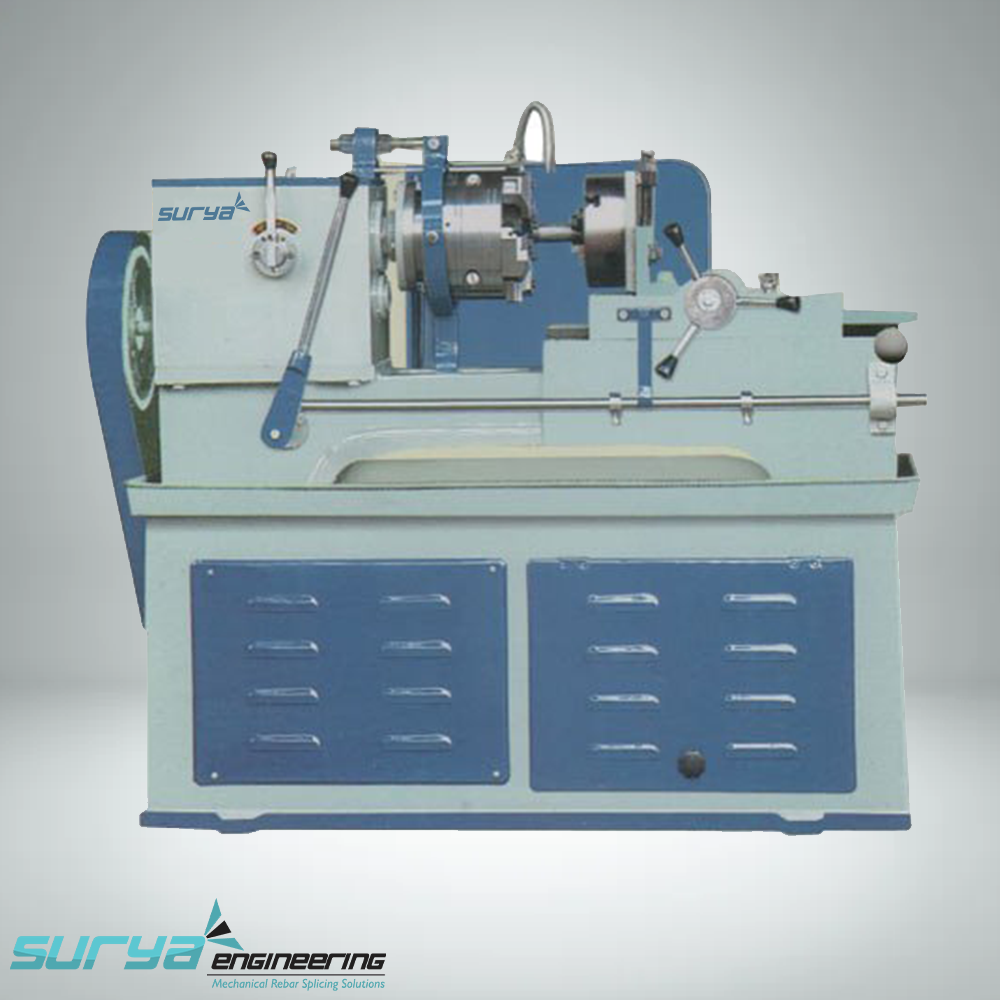

The Landis Threading Machine is a precision-engineered industrial solution designed for high-performance thread cutting, rolling, and grinding applications. Renowned for its reliability, accuracy, and durability, the Landis Threading Machine is a cornerstone in industries requiring superior thread quality and consistency. Ideal for manufacturing fasteners, automotive components, aerospace parts, and hydraulic systems, this machine combines cutting-edge technology with robust construction to meet the demands of modern production environments.

Key Features:

Precision Engineering:

Advanced CNC controls and servo-driven systems ensure micron-level accuracy for threads, pitches, and profiles.

Capable of handling both internal and external threading operations.

Versatile Threading Capabilities:

Supports a wide range of threading methods: single-point cutting, thread rolling, and thread grinding.

Compatible with materials including steel, aluminum, titanium, alloys, and plastics.

High-Speed Performance:

Optimized spindle speeds (up to 3,000 RPM) and rapid traverse rates for reduced cycle times.

Multi-axis synchronization for complex thread geometries (e.g., ACME, trapezoidal, and custom profiles).

Durability & Stability:

Heavy-duty cast iron construction with vibration-dampening properties for long-term precision.

Hardened guideways and ball screws ensure minimal wear and extended service life.

User-Friendly Operation:

Intuitive touchscreen interface with pre-programmed threading cycles and customizable templates.

Real-time diagnostics and error reporting for minimal downtime.

Automation Integration:

Compatible with robotic loaders, conveyors, and IoT-enabled systems for seamless production line integration.

Automatic tool changers (optional) for uninterrupted batch processing.

Safety & Compliance:

Emergency stop systems, protective enclosures, and safety interlocks.

Complies with ISO, CE, and OSHA standards.

Applications:

Automotive:Engine components, drive shafts, bolts, and nuts.

Aerospace:Landing gear threads, turbine parts, and high-strength fasteners.

Oil & Gas:Precision threads for pipes, valves, and drilling equipment.

General Manufacturing:Hydraulic cylinders, lead screws, and custom fittings.

Benefits:

Unmatched Accuracy:Delivers threads with tight tolerances (0.005 mm) for critical applications.

Increased Productivity:High-speed operation and automation reduce labor costs and boost output.

Cost Efficiency:Minimal material waste and energy consumption with optimized processes.

Future-Proof Design:Modular upgrades and software updates to adapt to evolving needs.

Technical Specifications:

Model Range:Manual, semi-automatic, and fully CNC-controlled variants.

Thread Diameter Capacity:2 mm to 300 mm (varies by model).

Spindle Speed:1003,000 RPM.

Power Supply:3-phase, 415V, 50/60 Hz (configurable).

Price:

Price 290000.0 INR / Piece

Minimum Order Quantity : 99 Pieces

Capacity : 1

General Use : CONSTRUCTION

Type : Broaching, Drilling, Turning, Chemical Machining, Laser Machining, Other, Milling, Etching

Price 203000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 50mm Milliliter (ML)

General Use : Industrial

Material : Other, Mild Steel